Mechanically reconditioned circular saw machine with the latest SIEMENS control to replace the current LCD display control unit MULTICOM / MMI

Machine Data

- Machine type: Vertical saw machine

- Manufacturer: Kaltenbach

- Modell: KKS 401 NA 1000

- Year range: 1990 – 2010

Technical specification

- NC-controlled rotary table -60°/0°/60°

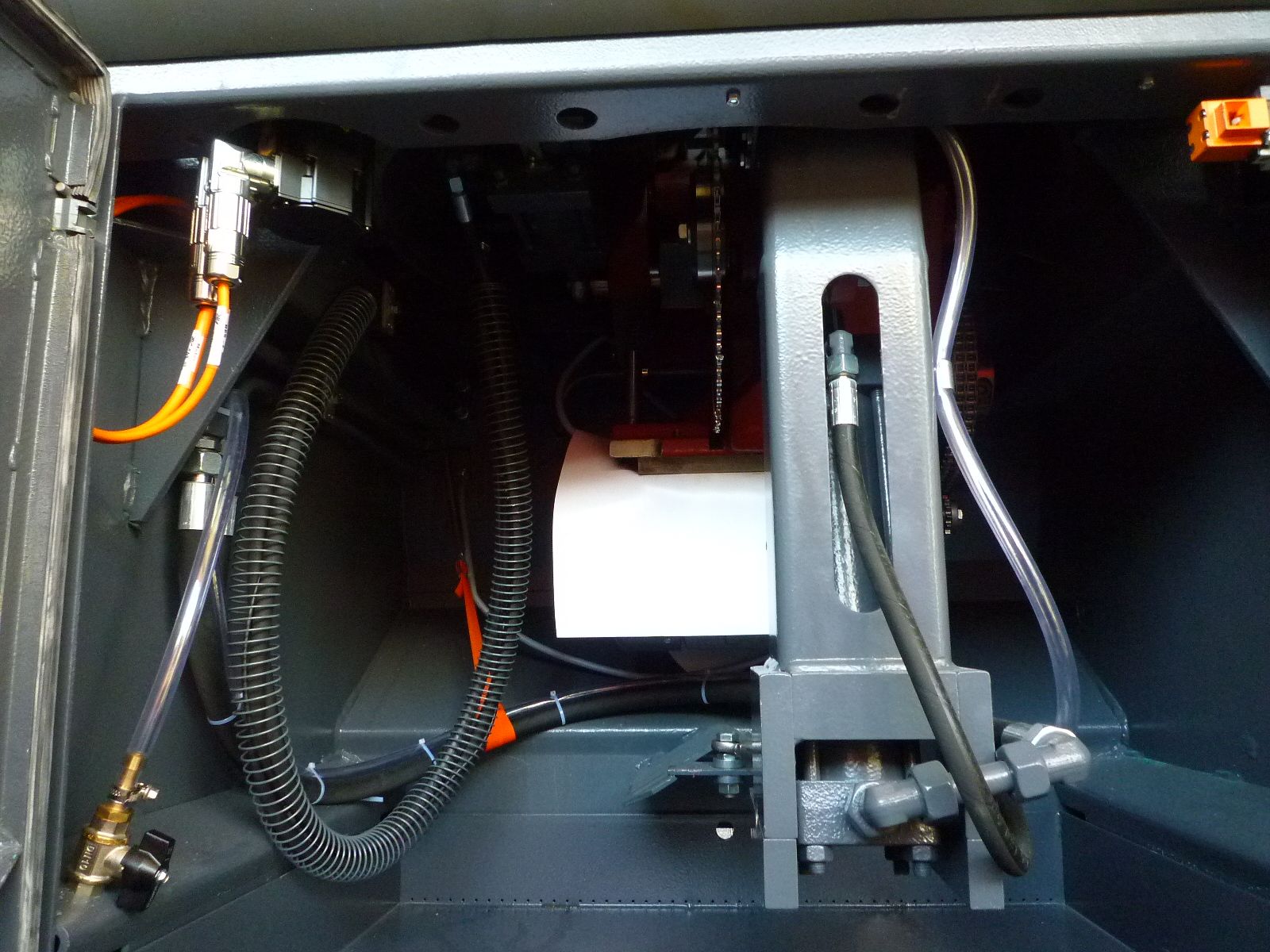

- Hydraulic workpiece clamping with long stroke clamping cylinders and clamping pressure reduction system “Omniprest”.

- Hydraulic saw blade feed

- Electronically adjustable saw blade stroke

- Pin chipping device of the saw blade

- Fixed workpiece stop for straight and mitre cuts on both sides

- CNC – controlled preselection of the cutting angle

- Machine operation via touch panel with EASYCUT-PRO software package

Technical Data

Cutting range

Mass and weights

Performance characteristics

Automatic Bar Infeed

- Flat magazine for pre-storage of round and rectangular material in addition to profiles

- High flexibility through fully-automatic infeed of a variety of materials

T3 Transport System for Circular Saws

- For material feed and removal with circular saws

- Ball-bearing light-running rollers

- Operating width: 330 mm / Roller diameter: 60 mm

T 4 Transport System for Circular Saws

- For material feed and removal with circular saws

- Solid rollers running in ball bearings, optionally available with drive

- Operating width: 390 mm / Roller diameter: 60 mm

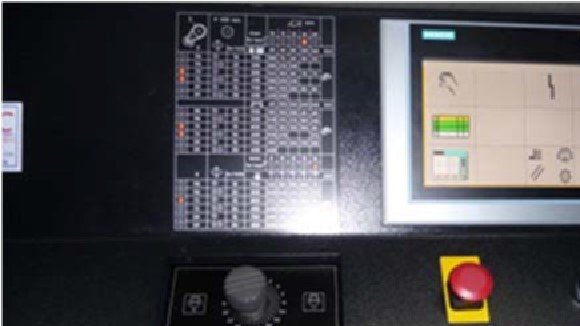

Machine operation by touch panel with software package EASYCUT-PRO, consisting of:

Hardware

PLC Siemens S7-1500

Equipment with modern SIEMENS TOUCH Panel TP 900 in industrial quality

· Color touchscreen with big sized keypads

· Operator interface EASYCUT-PRO with the operating system Windows CE 6.0

Hardware network connection of the computer equipment to a central computer or client network is optional.

Software

Input and sequence functions EASYCUT-PRO

input functions

· Entering the part dimensions on part graphed visualization

· Machine control buttons for the manual and automatic functions.

· OverviewAmenitiesPicture menu of new orders already entered, the processing status (in progress, finished and semi-worked) can be seen.

· Graphical representation of the cross section with the location to the workpiecefence.

· Workpiece dimensions according to the present drawings of a customer.

· Processing Types: piece-oriented, rod-oriented

Possibilitys of data transfer

1. Data input directly by the operator at the control panel on the machine.

2. Import data with CSV file, the data must by the EASYCUT-PRO program are matched.

This controller update, designed to replace the old MULTICOM LCD controls can be carried out at the existing at your machine.

Alternatively, swap your machine against an overhauled machine from our stock, we will trade in your machine.